- CLADDING

- SPECIALISED BUILDING MATERIALS (SBM)

- PARQUET AND DECKING

- TIMBER

- SHOWERS CABINS / DOORS

- SPA

- ACCESSORIES AND FURNITURE

- MIXERS

- SHOWER TRAYS

- BATH TUBS

- WC AND BIDET

- WASH BASINS

- SANITARY WARE AND ACCESSORIES

- CERAMICS

- MOSAICS

- PATTERNED TILES

- PLAIN COLOURS

- SAND LOOKING

- CEMENT LOOKING

- STONE LOOKING

- WOOD LOOKING

- MARBLE LOOKING

Veneer refers to very thin slices of wood typically between 0.5 to 1mm in thickness. They are obtained either by peeling a tree log or by slicing large rectangular blocks of wood. Nearly each species of wood has its veneer available. The veneer has the ability to be joined with other veneers to form a large surface sheet which is often glued on a panel e.g. chipboard, MDF or Plywood thus enabling the woodworker to produce a wooden item e.g. a table top, a cupboard or a cabinet that would either be impossible to be produced with solid wood or would be extremely expensive. If an Oak tree is peeled, then it will produce Oak veneer with appearance and grain of Oak. There is no further process being done to change the appearance of the wood. The same applies for all wood species. They are called real wood veneers.

In the case of technical veneers, real wood veneers of species such as Poplar, Lime Wood and Ayous are broken down and reassembled into infinite varieties, finishes and decorative effects through a particular process that peels the log, then dyeing the wood by immersion, after which the dyed sheets are layered to create a new log (technical wood veneers).

Our stock comprises of both real wood veneers and technical wood veneers.

Product Categories

- CLADDING

- SPECIALISED BUILDING MATERIALS (SBM)

- PARQUET AND DECKING

- TIMBER

- SHOWERS CABINS / DOORS

- SPA

- ACCESSORIES AND FURNITURE

- MIXERS

- SHOWER TRAYS

- BATH TUBS

- WC AND BIDET

- WASH BASINS

- SANITARY WARE AND ACCESSORIES

- CERAMICS

- MOSAICS

- PATTERNED TILES

- PLAIN COLOURS

- SAND LOOKING

- CEMENT LOOKING

- STONE LOOKING

- WOOD LOOKING

- MARBLE LOOKING

REAL WOOD VENEERS

We keep in stock a wide variety of real wood veneers, which can be glued on panels such as MDF boards, chipboard and plywood. We keep in stock the following veneer varieties. Special finishes and varieties available upon special order.

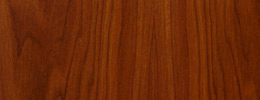

Varieties: American Walnut

American Walnut

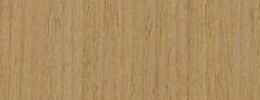

Red Oak

Red Oak

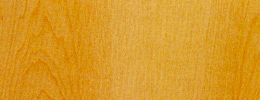

Oak Quarter Cut

Oak Quarter Cut

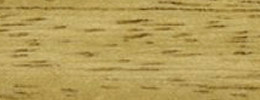

Maple

Maple

Iroko

Iroko

European Walnut

European Walnut

European Cherry

European Cherry

Beech

Beech

TECHNICAL VENEERS

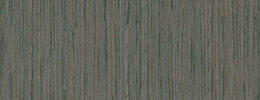

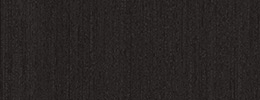

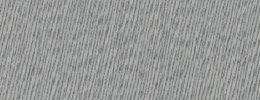

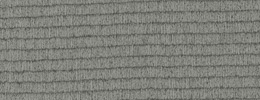

We are proud to cooperate with ALPI, the leader in the field of technical veneers. Alpi produces technical veneers obtained by glueing, pressing and slicing sheets of dyed wood made from veneer of poplar, lime wood or Ayous. Technical veneers can resemble the colours and grains of kind of real wood veneers or could be any other creative structure with patterns that cannot be found in nature, with original chromatic effects. Technical wood veneers, retain all the physical characteristics of real wood while simultaneously can be made to the all wood defects such as knots and grain irregularities. The ALPI veneer can also be provided prefinished with state-of-the-art products and varnishes to bring out its natural beauty. We keep a wide range of finishes in stock and the rest of the collection can be provided at a short lead time (c.2-3 weeks). Below is some of the finishes we keep in stock. Finishes: Alpi Grey Dark Grey Oak

Alpi Grey Dark Grey Oak

Alpi Grey Gabon Ebony

Alpi Grey Gabon Ebony

Alpi Grey Platinum Oak

Alpi Grey Platinum Oak

Alpi Grey Smoke Grey

Alpi Grey Smoke Grey

Alpi Makkasar Ebony

Alpi Makkasar Ebony

Alpi Nordic Decape Oak

Alpi Nordic Decape Oak

Alpi RV Walnut Crown Cut

Alpi RV Walnut Crown Cut

Alpi RV Walnut Quarter Cut

Alpi RV Walnut Quarter Cut

Alpi Sand Breeze Oak

Alpi Sand Breeze Oak

Alpi Sand Natural Oak

Alpi Sand Natural Oak

Alpi Sand Titanium Oak

Alpi Sand Titanium Oak

Alpi Textiled Concrete Pinstripe

Alpi Textiled Concrete Pinstripe

Alpi Textiled Day and Night Twill

Alpi Textiled Day and Night Twill

Alpi Textiled Smoky Velvet

Alpi Textiled Smoky Velvet

Alpi Zebrano Quarter Cut

Alpi Zebrano Quarter Cut

Pierro Lissoni Alpi Ikat 1 Dark Grey

Pierro Lissoni Alpi Ikat 1 Dark Grey

Pierro Lissoni Alpi Ikat 3

Pierro Lissoni Alpi Ikat 3

Pierro Lissoni Alpi Xilo 2.0 Striped Grey

Pierro Lissoni Alpi Xilo 2.0 Striped Grey

Pierro Lissoni Alpi Xilo 2.0 Striped Sand

Pierro Lissoni Alpi Xilo 2.0 Striped Sand

Pierro Lissoni Alpi Xilo 2.0 Striped White

Pierro Lissoni Alpi Xilo 2.0 Striped White